Secondary battery plant

Cathode Material Production Plant

Secondary Battery Recycling Plant

Provide technology-intensive EPC integrated solutions for

cathode material production and secondary battery recycling facilities.

As a field that requires various technologies including powder handling, conveying, and thermal treatment, we have the best team of experts in Korea who can provide solutions.

- Experience in Lithium Hydroxide Production Facility

- Performance of lithium carbonate drying, milling, and packaging facility package for a secondary battery recycling project

- EPC integrated solution for production and recycling plants related to cathode materials

Related Performance

| NO. | Project | Summary | item | Customer | Year |

|---|---|---|---|---|---|

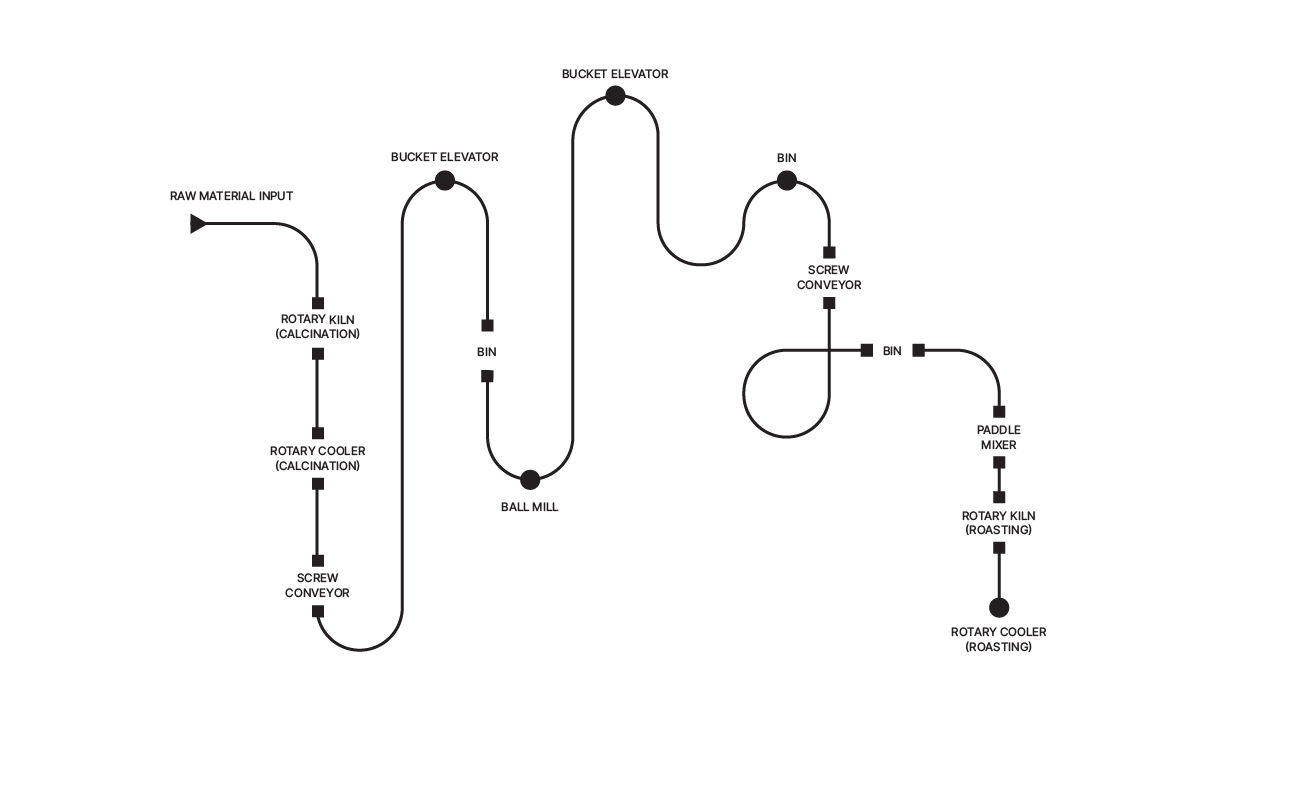

| 1 | POSCO PosLX ME CO Upstream Calcination and Roasting Process | Facilities that calcines and crushing lithium ore, mixes it with sulfuric acid, and roasts it | ROTARY KILN, ROTARY COOLER, BALL MILL, PADDLE MIXER, SCREW CONVEYOR, BUCKET ELEVATOR, ETC | POSCO | 2018 |

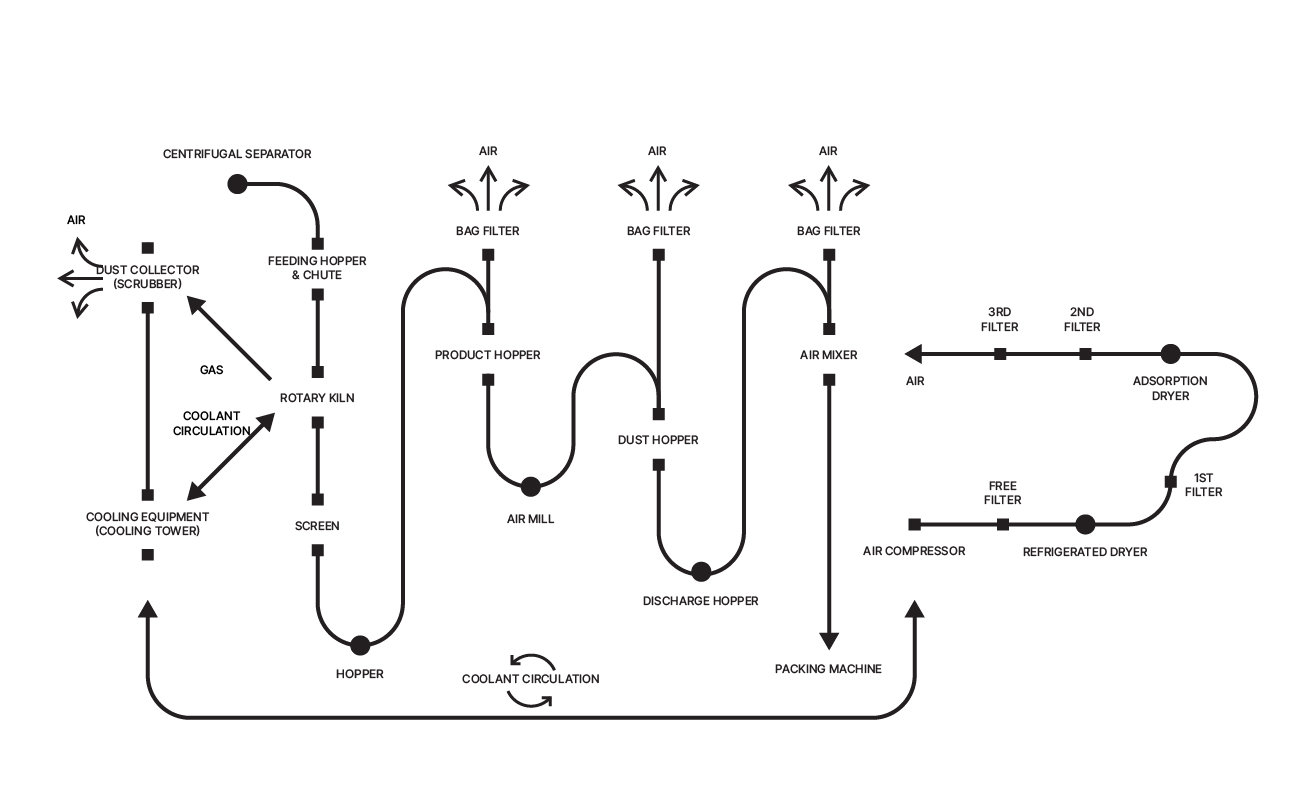

| 2 | POSCO HY Clean Metal Co. Ltd. Lithium Carbonate Productization Facility | Facilities that dehydrates, dries, and pulverizes lithium carbonate slurry to make and pack lithium carbonate | CENTRIFUGAL SEPARATOR, ROTARY KILN, SCREEN, AIR MILL, AIR MIXER, SCREW CONVEYOR, PACKING MACHINE, ETC | POSCO HY CLEAN METAL | 2021 |

| 3 | Ore Lithium Commercialization PJT_ Plant 2 Leach Refinery (EP Contract) Input Equipment | Equipment that inputs subsidiary materials prior to the lithium leaching process | BAG BREAKER, FEED HOPPER, DUST COLLECTOR, STORAGE BIN, ROTARY VALVE, AGITATOR, STEEL STRUCTURE | SNNC | 2022 |

Representative Projects

Overview

Customer

POSCO

Location

POSCO Kwangyang plant

Year of ordering

2018

Summary

Facility that calcines and crushing lithium ore, mixes it with sulfuric acid, and roasts it

Requirement

Raw Material Spec

Material : Spodumene

Design Condition

- Calcination condition

Temperature : 1070℃

Capability : 3 Ton/hr - Roasting Condition

Temperature : 250 ℃

Capability : 4 Ton/hr

Flow Diagram

Related Equipment

Rotary Kiln(Calcination)

Rotary Cooler

(Calcination)

Mill

Mixer

Rotary Kiln (Roasting)

Rotary Cooler (Roasting)

Screw Conveyor

Bucket Elevator

Overview

Customer

POSCO HY CLEAN METAL

Location

HY Clean Metal plant(Yulchon Industrial Complex)

Year of ordering

2021

Summary

Facilities that dehydrates, dries, and pulverizes lithium carbonate slurry to make and pack lithium carbonate

Requirement

Raw Material Spec

1. Material : Lithium Carbonate Slurry

2. Concentration: 15~30%

3. PH : 7~9

4. Temperature : ~90℃

5: Particle size distribution : D50<20um

Design Condition

1. Humidity :≤ 0.15%

2. Specific gravity :0.3~0.4t/m³

3. Temperature :≤ 50℃

4. Particle size :≤ 15μm

5. Capacity : 2 ton/hr

Flow Diagram