Calcination · Drying

· Incineration Plant

Raw Material Calcination Plant

Production Drying Plant

Sludge Incineration Plant

Customized engineering solutions for calcination, drying and incineration

We supply complete systems for calcination, drying and incineration plants for a variety of materials, from powder-type products to slurries for recycling and waste sludge.

ㅤ

ㅤ

- Design aligned with global standards

- Steady order performance and technology

- From customized design to construction and meticulous post-management.

Related Performance

| NO. | Project | Summary | item | Customer | Year |

|---|---|---|---|---|---|

| 1 | STS 1Steelmaking Byproduct Wet Sludge Drying Facility Installation | Reuse plant for drying and briquetting SUS by-products (raw material residue) |

Belt Conveyor, Flex wall Conveyor, Rotary Kiln, Dust Collector | POSCO | 2013 |

| 2 | (Chile) PLAMENT PROJECT OSTC & FEEDING SYSTEM | Heating and melting equipment for copper sludge (SLIME) | FURNACE, Burner, Transfer Car, Screw Conveyor, Dust Collector | LS-Nikko | 2014 |

| 3 | RDMP RU-V BALIKPAPAN PJT (SLUDGE) | Equipment that incinerates waste sludge | Dryer, COMBUSION CHAMBER (1ST, 2ND), Dust Collector | Hyundai Engineering |

2022 |

| 4 | Fabrication, transportation, and installation of the torrefaction system. | Facility for torrefaction by heating sugar cane by-products after pelletizing | Chain Conveyor, Pelletizer, Screen, Bucket Elevator, Rotary Kiln, Gas Mixer | INSTITUTE FOR ADVANCED ENGINEERING | 2023 |

Representative Projects

Torrefaction Plant

Waste Sludge Incineration Plant

Torrefaction Plant

Overview

Customer

INSTITUTE FOR ADVANCED ENGINEERING

Location

Vietnam Tay Ninh, TTC fertilizer factory

Year of ordering

2021

Summary

Facility for torrefaction by heating sugar cane by-products after pelletizing

Requirement

Raw Material Spec

- Name : Sugar Cane Bagasse

- Apparent density: 100 kg/㎥

- Specific heat : 0.359 kcal/kg℃

- Moisture content: 40wt%

- Pellet properties

1) density 600 kg/㎥

2) Less than 10mm in diameter

3) Less than 30mm in length

Design Condition

- Torrefaction temperature: 260 ~ 280 ℃ : 260~280℃

- Capacity : 1.48 ton/hr(Product)

- Target moisture content : 2.5wt%

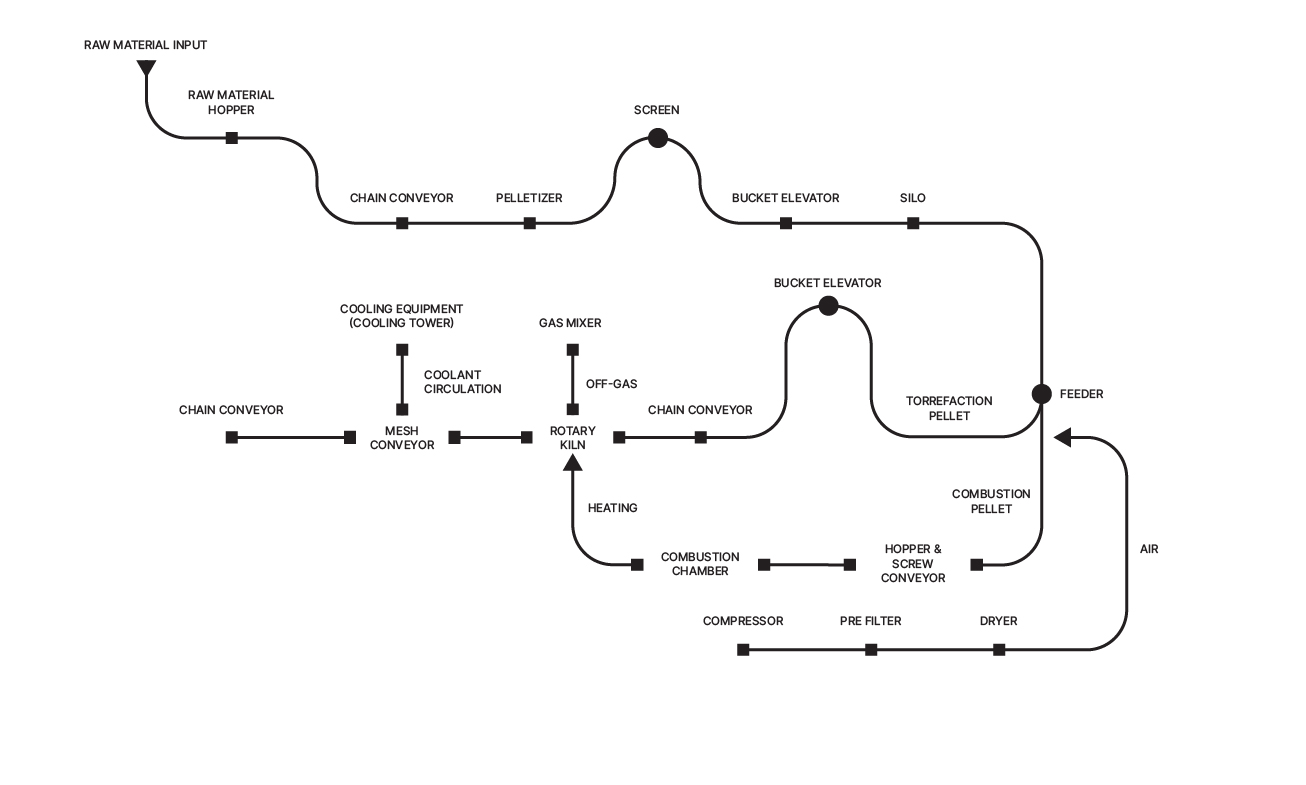

Flow Diagram

Related Equipment

Torrefaction

Chain Conveyor

Capa : 3,400 kg/hr

Torrefaction

Pelletizer

Capa : 3,400 hr

Type : Including Pellet Cutter

Torrefaction

Screen

Capa : 3,400 hr

Torrefaction

Bucket Elevator

Capa : 3,400kg/hr

Speed : 60M/MIN

Torrefaction

Rotary Kiln

Capa : 2,800 kg/hr

Type : Indirect Firing(Oil Burner)

Torrefaction

Gas Mixer

Capa : 22,484 N㎥ / hr

Type : Insulator(Castable, Ceramic & Glass Wool)

Torrefaction

Silo

Capa : 30 ton

Torrefaction

Combustion Chamber

Capa : 600 Mcal/h

Type : Oil Burner

Torrefaction

Cooling Tower

Capa : 30 R/T

Type : FRP

Waste Sludge Incineration Plant

Overview

Customer

Hyundai Engineering

Location

Indonesia Balikpapan

Year of ordering

2022

Summary

Equipment that incinerates waste sludge generated in oil refineries after drying

Requirement

Raw Material Spec

1. Name : Waste Sludge

2. Moisture content: 80wt%

Design Condition

1. Capacity : 37,198 N㎥/h

2. Processing temperature : : 1,020℃

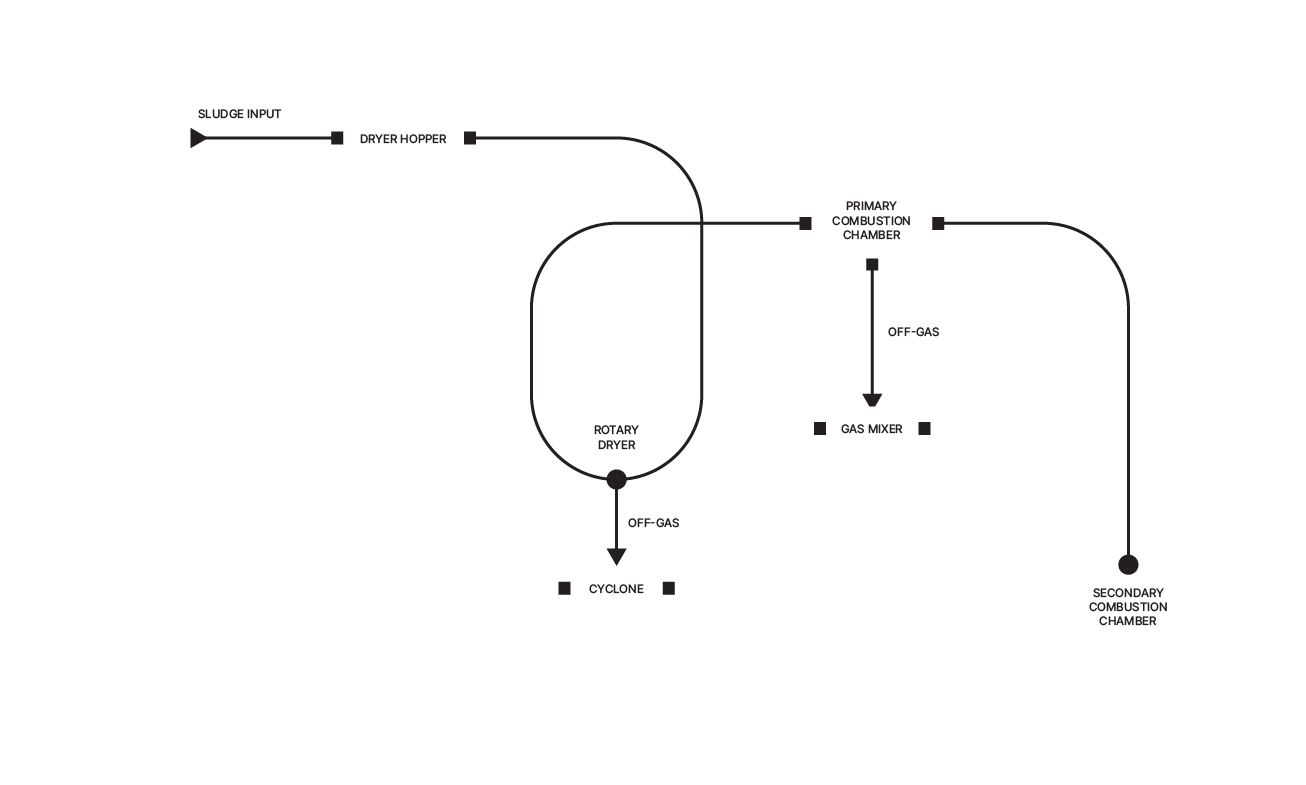

Flow Diagram

Related Equipment

Waste Sludge Incineration

DRYER HOPPER

Capa : 32 ㎥

Waste Sludge Incineration

ROTARY DRYER

Capa : 5,000kg/hr

Design Temperature : 670℃

Waste Sludge Incineration

CYCLONE

Capa : 19,000 N㎥ / hr

Design Temperature : 350 ℃

Waste Sludge Incineration

PRIMARY COMBUSTION CHAMBER

Capa : 1,540 kg/hr

Design Temperature : 1200℃

Waste Sludge Incineration

GAS MIXER

Capa : 14,772 ㎥ / hr

Design Temperature : 670 ℃

Waste Sludge Incineration

SECONDARY COMBUSTION CHAMBER

Capa : 37,000 N㎥ / hr

Design Temperature : 1200℃