-

Drying Equipment

Calcination Equipment

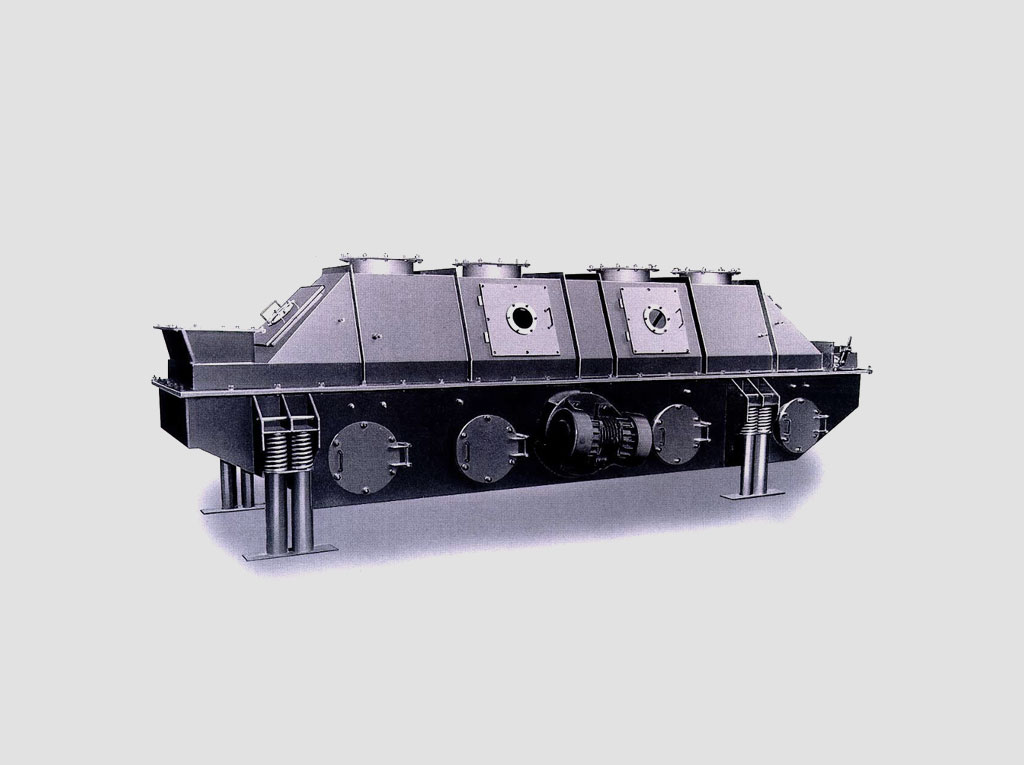

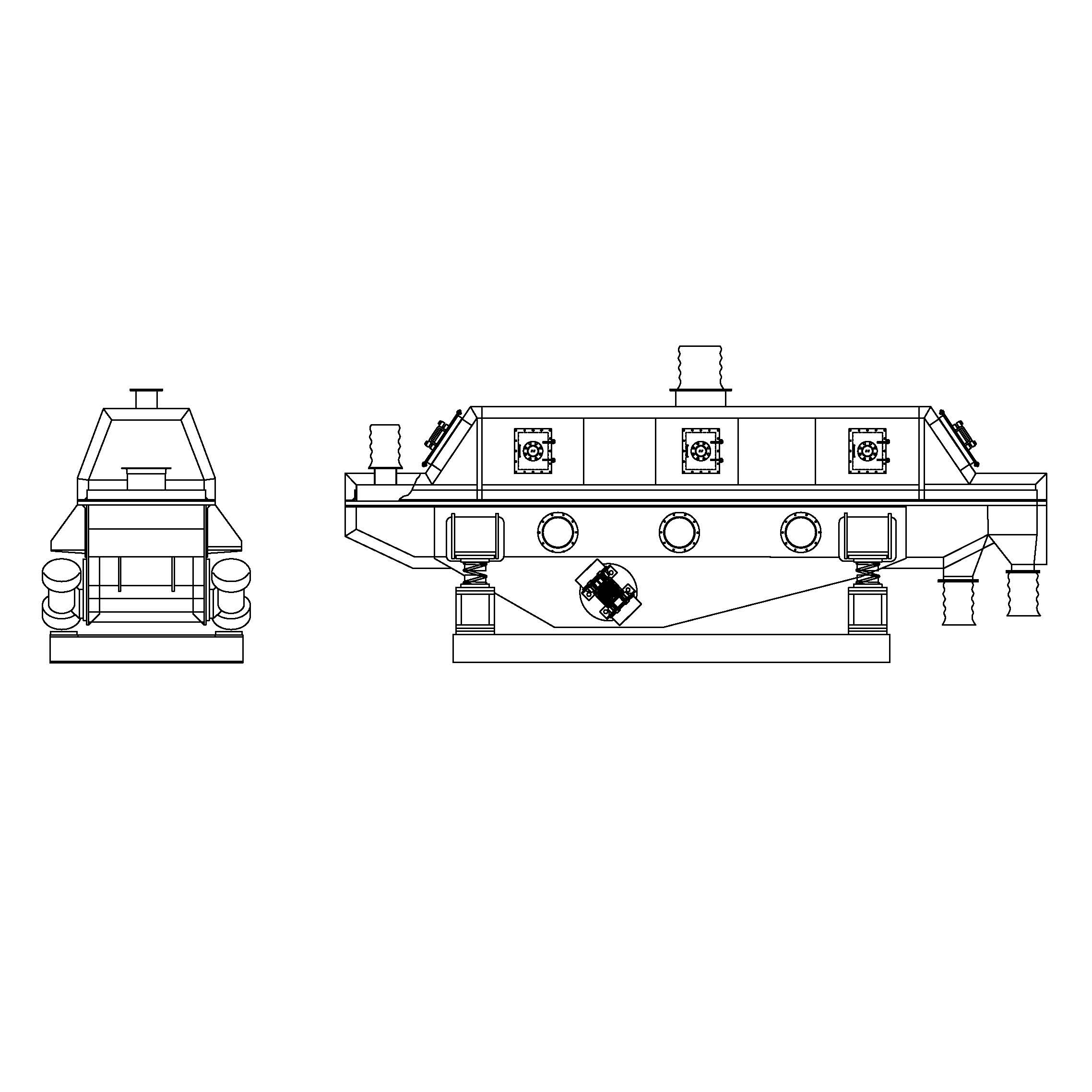

Vibration Fluidized Bed Dryer

Vibration Fluidized Bed Dryer

-

Drying Equipment

Calcination Equipment

It is a drying device that adds the force of a vibration motor to a fluidized bed dryer for smooth material transfer and uniform fluidized bed formation and is called a vibrating fluidized bed dryer or a vibrating conveyor dryer.

● No damage of material in process

● Easy to adjust the residence time with variable vibration motor

● Excellent drying efficiency by high heat capacity

● Enable continuous autopilot

● Small drive unit and easy to operate and maintenance

● Flake of organic/inorganic compounds.

● Granulated materials (Food, catalyst, zeolites, fertilizers)

● Powder of a certain particle size.

●

●

●

Related Equipment

Calcination Equipment

GCD dryer(Grind Classifying Dryer) is a continuous flow drying equipment that simultaneously handles drying, grinding, and classification. It allows to control particle size of the material through the adjustment of the rotational speed of the grinding and classification units.

Calcination Equipment

Rotary kiln is a horizontal cylindrical rotary drying/firing device, which is divided into direct heating type that supplies hot air and indirect heating type that heats the body according to the heat source supply method.

The direct heating type is categorized into counter current and co-current type according to the flow direction of hot air and materials.

The counter current rotary kiln has high thermal efficiency, but it is not suitable for materials with thermal deformation at the heating temperature.

The co-current rotary kiln has lower thermal efficiency compared to convection type, but it is more free from thermal deformation of materials.

Calcination Equipment

The rotary cooler, which is a kind of cooler, is a cylinder type high efficiency rotating cooler. It is a furnace in which raw material is put into a rotary cylinder made of steel and directly cooled or indirectly cooled. It is mainly used to cool the product after chemical reaction or physical change by treating the material at high temperature.