-

Drying Equipment

Calcination Equipment

Rotary Vacuum Dryer

Rotary Vacuum Dryer

-

Drying Equipment

Calcination Equipment

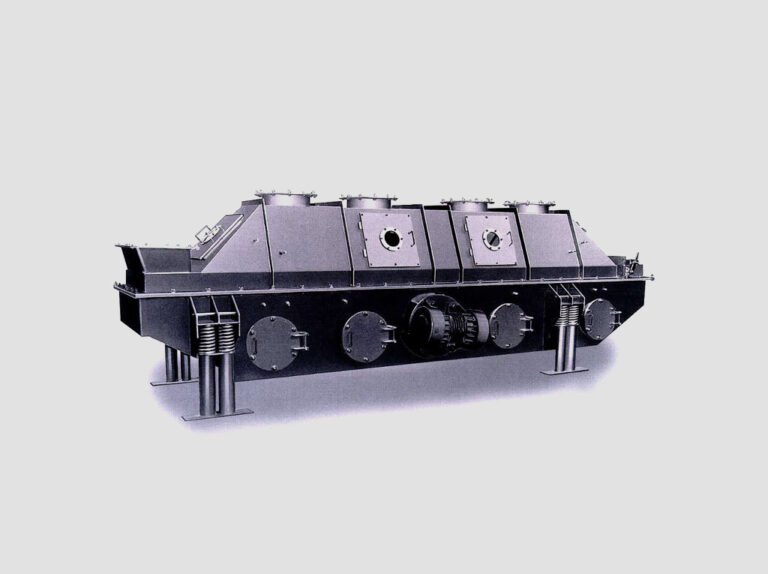

Rotary vacuum dryer is low-temperature drying equipment through vacuum manipulation. It is suitable for drying substances that undergo phase-change at high temperatures.

- Capable to low-temperature drying in vacuum.

- Capable to dry and recovery the volatile organic solvents

- It is efficient to dry heat-sensitive materials.

- Fast drying speed as providing heat to the rotating shaft

- Wide range of applications such as powders, particle, sludge

- Safety by operation in low temperature

- Sludge

- Low heat-resistance food ( ex. powders)

- Compounds contained organic solvents.

- Recovery of solvents from organic dyes and pigments

- Phase-changed materials at high temperatures.

Related Equipment

Calcination Equipment

GCD dryer(Grind Classifying Dryer) is a continuous flow drying equipment that simultaneously handles drying, grinding, and classification. It allows to control particle size of the material through the adjustment of the rotational speed of the grinding and classification units.

Calcination Equipment

Rotary kiln is a horizontal cylindrical rotary drying/firing device, which is divided into direct heating type that supplies hot air and indirect heating type that heats the body according to the heat source supply method.

The direct heating type is categorized into counter current and co-current type according to the flow direction of hot air and materials.

The counter current rotary kiln has high thermal efficiency, but it is not suitable for materials with thermal deformation at the heating temperature.

The co-current rotary kiln has lower thermal efficiency compared to convection type, but it is more free from thermal deformation of materials.

Calcination Equipment

The rotary cooler, which is a kind of cooler, is a cylinder type high efficiency rotating cooler. It is a furnace in which raw material is put into a rotary cylinder made of steel and directly cooled or indirectly cooled. It is mainly used to cool the product after chemical reaction or physical change by treating the material at high temperature.