Material Handling Plant

Material Handling Plant

Comprehensive solution for material transfer and supply of products,

including conveying equipment and integrated front and rear equipment.

We provide a comprehensive package of storage equipment, transfer equipment,

screening equipment, supply equipment, environmental equipment, and packaging equipment necessary for raw material supply and product disposal.

- Differentiated competitiveness built up through years of performance

- Package proposals from experts with creativity and passion

- Realization of technological innovation through perfect design

Related Performance

| NO. | Project | Summary | Items | Customer | Year |

|---|---|---|---|---|---|

| 1 | POSCO SLUDGE RETREATMENT FACILITY |

Sludge & dust transfer and mixing equipment | Feeder, Belt Conveyor, Mixer, Screen, Bucket Elevator |

POSCO | 2005 |

| 2 | ASH & SAND HANDLING SYSTEM APRON CONVEYOR | Facility that mixes ASH generated after incineration with sand and filters it to discharge only ASH | SILO, CHAIN CONVEYOR, SCREW CONVEYOR, SCREEN, PNEUMATIC CONVEYOR SYSTEM, BUCKET ELEVATOR | JEONJU PAPER | 2009 |

| 2 | SEAH_M&S, FE-MN RAW MATERIAL COMPOUNDING FACILITY | FE-MN raw material mixing equipment | Feeder, Belt Conveyor, Drum Mixer | SEAH M&S | 2012 |

| 4 | POSLX ME CO UPSTREAM_ RAW MATERIAL HANDLING SYSTEM | Facility that screen lithium ore by particle size and moves it to a calcining rotary kiln | BIN, SCREW CONVEYOR, BUCKET ELEVATOR, FLOW CONVEYOR, VOLUMETRIC FEEDER, CIRCLE FEEDER | POSCO | 2018 |

Representative Projects

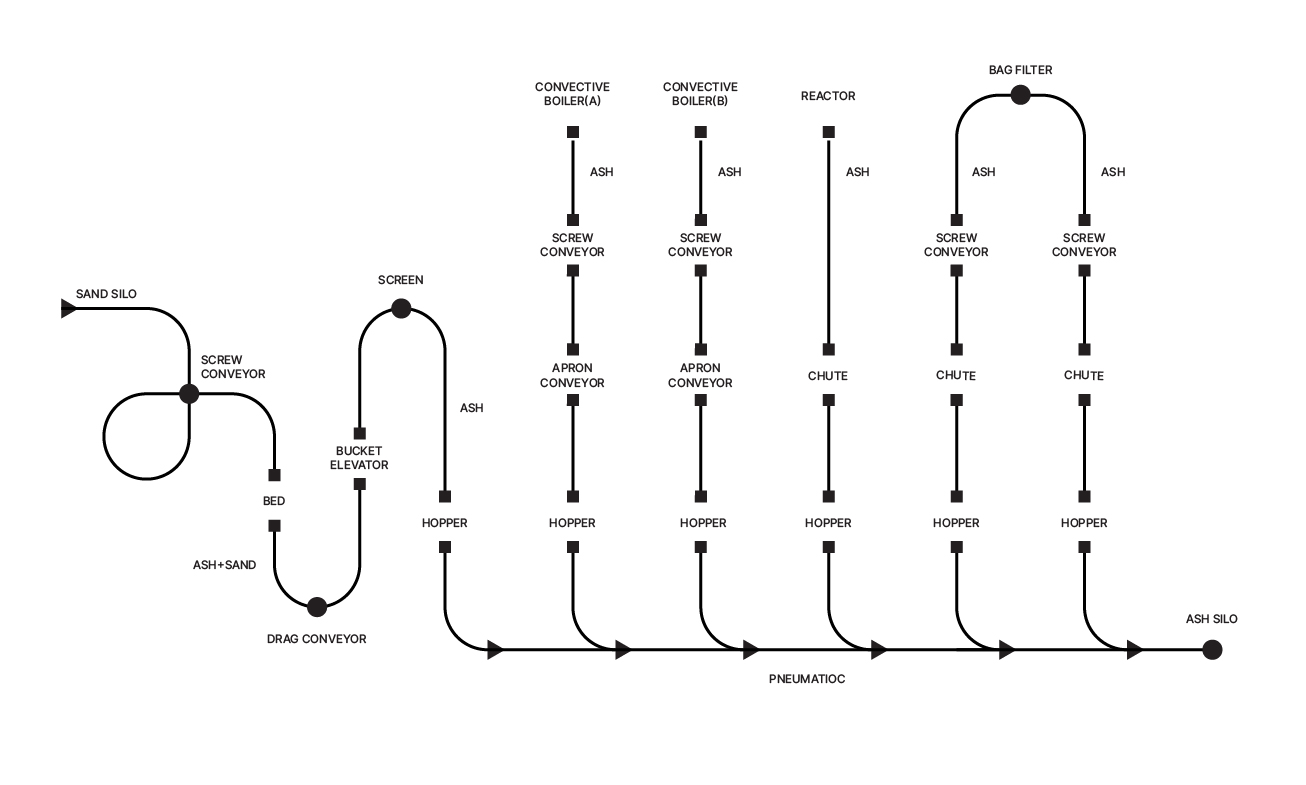

Overview

Customer

Jeonju Paper

Location

Jeonju

Year of ordering

2009

Summary

Facility that mixes ASH generated after incineration with sand and filters it to discharge only ASH

Requirement

Raw Material Spec

Material : SAND, ASH

Design Condition

Capacity : 5㎥/hr ~ 10 ㎥/hr

Flow Diagram

Related Equipment

Screw Conveyor

Drag Chain Conveyor

Screen

Bucket Elevator

Overview

Customer

POSCO

Location

POSCO Kwangyang plant

Year of ordering

2018

Summary

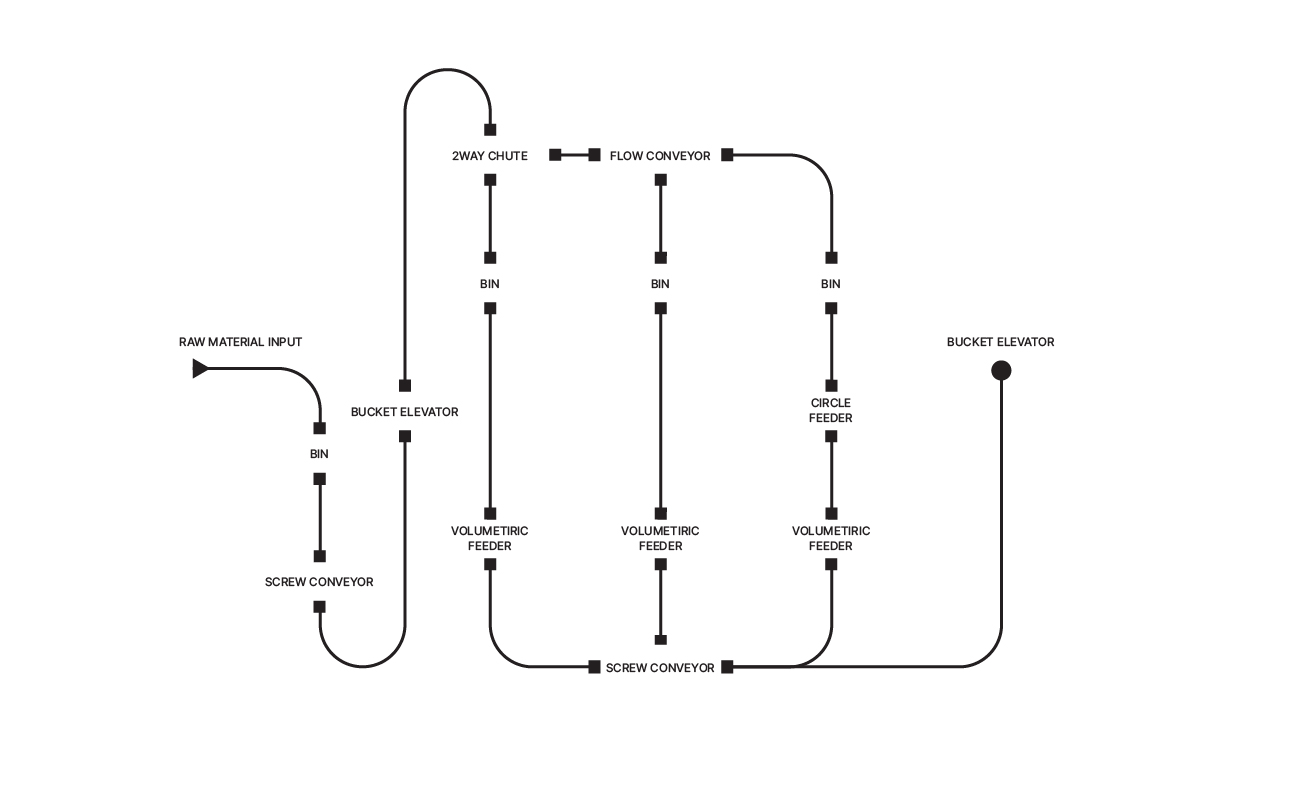

Facility that screen lithium ore by particle size and moves it to a calcining rotary kiln

Requirement

Raw Material Spec

Material: Spodumene

Design Condition

Capacity : 18 TON/hr

Flow Diagram